A jaw crusher is a mechanical device used in the mining and construction industries for the primary and secondary crushing of rocks and ores. It is designed to break down large blocks of hard, abrasive materials into smaller, manageable pieces. The jaw crusher operates based on the principle of compression and can handle a variety of materials, from soft to extremely hard rocks.

The jaw crusher operates through two jaws: one fixed and the other movable. These two jaws create a V-shaped cavity, where the material is fed into. As the movable jaw moves back and forth, it compresses and crushes the material against the fixed jaw. The material is crushed in the zone between the jaws, and once the movable jaw moves away from the fixed jaw, the crushed material is discharged from the machine at the bottom. The size of the discharge material is determined by the gap between the two jaws, which can be adjusted to meet the desired output size.

There are two main types of jaw crushers:

Single-toggle Jaw Crusher

In a single-toggle jaw crusher, the movable jaw is supported by a bearing on an eccentric shaft driven by the pitman. The pitman is connected to the movable jaw through a toggle plate, creating an elliptical motion. This design allows the jaw crusher to apply both pressure and friction forces to the material being crushed. Single-toggle jaw crushers are typically used in the aggregate industry for medium-hard materials.

Double-toggle Jaw Crusher

In contrast, the double-toggle jaw crusher has two toggle plates and operates with a more complex mechanism. The pitman is mounted on a fixed, non-eccentric shaft and is driven by a camshaft. This setup applies only pressure on the material, making it more suitable for crushing very hard, abrasive materials. The double-toggle mechanism also provides a longer lifecycle due to the absence of friction forces. These crushers are often used in applications where durability and robustness are key.

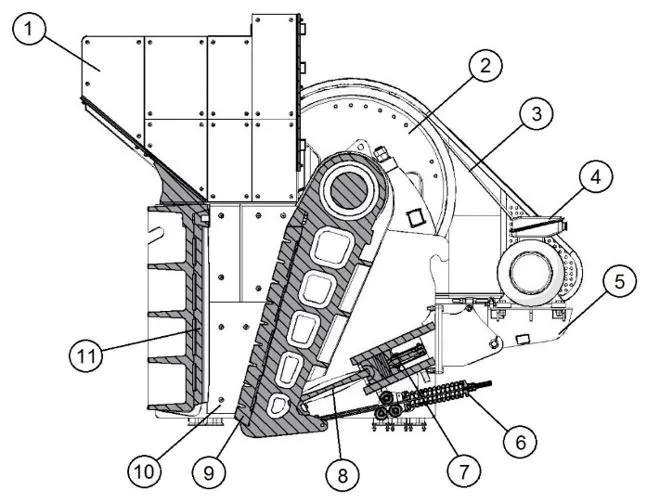

A typical jaw crusher consists of several important parts that work together to ensure its functionality:

Feed Chute: The feed chute directs material into the crushing chamber.

Drive Flywheel: This is connected to the eccentric shaft and helps to smooth the operation by storing and releasing energy.

Electric Motor and V-belts: The electric motor drives the flywheel through V-belts, providing the necessary rotational force.

Hydraupc Cypnder: Used for adjusting the jaw settings to control the size of the discharge material.

Toggle Plate: The toggle plate ensures the movement of the movable jaw, transmitting force from the flywheel to the crushing action.

Swing Jaw and Fixed Jaw: The swing jaw moves back and forth, crushing material between the jaws, while the fixed jaw remains stationary.

Discharge Area: The material exits the crushing chamber here once it has been sufficiently broken down.

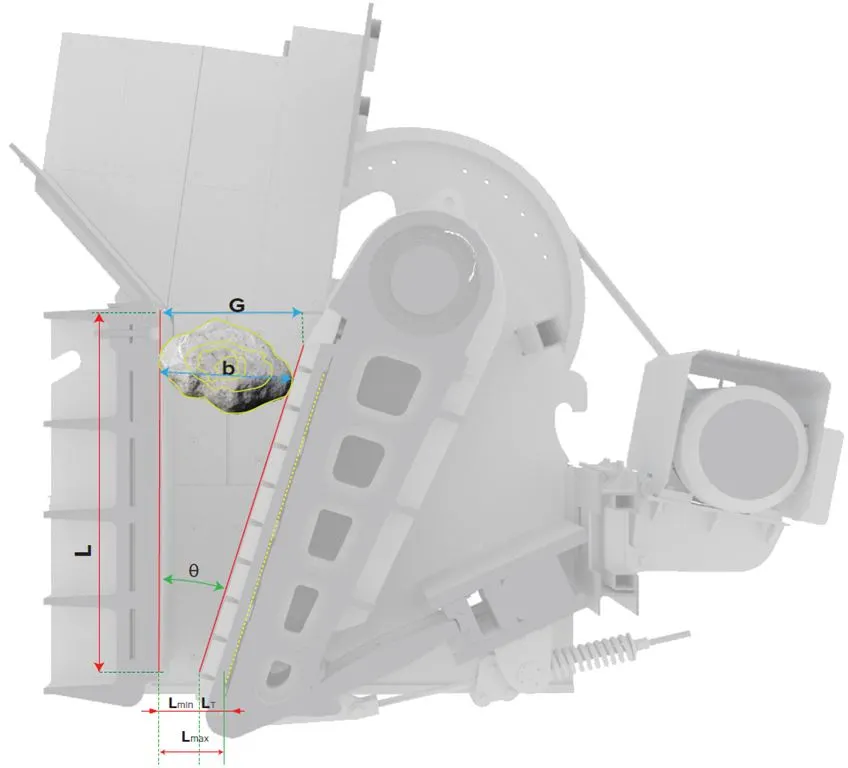

The efficiency and output of a jaw crusher are largely determined by the following technical parameters:

Gape Width: This is the opening at the top of the jaw crusher where the material enters.

Closed Side Setting (CSS): The smallest possible gap between the fixed and movable jaws, which determines the size of the crushed material.

Stroke Length: The vertical distance the movable jaw moves during a single cycle. This is related to the Open Side Setting (OSS) and Closed Side Setting (CSS).

Nip Angle: The angle between the movable and fixed jaws, which determines the ability of the jaws to grip the material. A proper nip angle ensures that material does not slip during crushing.

Size Reduction Ratio: This ratio, often between 1/3 and 1/4, represents the proportion of the feed size to the desired product size. It is a critical factor in determining the machine's capacity and efficiency.

Advantages:

High efficiency: Jaw crushers are well-suited for large-scale production and can process a wide range of materials.

Versatility: They can crush a variety of material types, from soft to very hard rocks.

Durability: When properly maintained, jaw crushers can provide a long service life, especially the double-toggle models.

Disadvantages:

Wear and tear: The frequent contact with hard materials can cause significant wear on the machine components, particularly the jaw plates.

Energy consumption: Jaw crushers, especially single-toggle types, tend to consume more energy when dealing with hard materials.

Size limitations: They are typically limited in terms of the maximum size of the material they can process effectively.

Jaw crushers are primarily used in the mining, construction, and demolition sectors. They are ideal for breaking down large, hard rocks and ores into smaller, more manageable pieces. Some common applications include:

Mining: Crushing ores for further processing, such as in gold, copper, and coal mines.

Construction: Breaking large rocks into smaller sizes for use in construction materials like concrete.

Recycling: Crushing concrete, asphalt, and other demolition materials to be reused in new construction projects.

Choosing the right jaw crusher depends on various factors such as the nature of the material to be crushed, desired output size, and operational requirements. Some key considerations include:

Material Type: Different materials, such as hard rock, soft rock, or recycled concrete, will require different jaw crushers in terms of size, type, and power.

Output Size: Ensure the jaw crusher can provide the desired particle size for the next phase of processing.

Production Capacity: The machine should be able to handle the required volume of material efficiently.

Maintenance: Consider the ease of maintenance and the availability of spare parts for the crusher to ensure a longer service life.