Raw material and energy costs increase continuously.

Safety of persons and assets requires improvement.

Standardisation of equipment is difficult to achieve.

Production

capacity

Processing

quality

Assets health

Energy

efficiency

Mining safety

Remote monitoring

Remote monitoring

1. Eliminate geographical restrictions.

2. Close the technological gap.

3. Analysis of data to optimise operations.

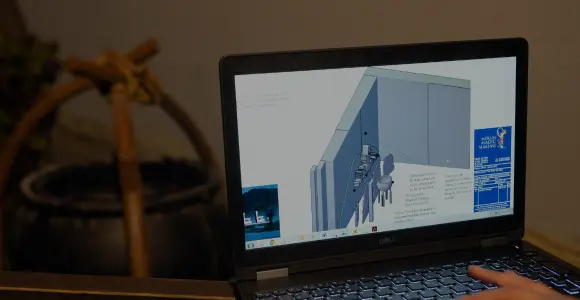

Operation management system

Operation management system

1. Collect data and calculate KPI automatically

2. Provide 24/7 real-time help by experts.

• Extend uptime

• Incomparable energy efficiency.

• Extend equipment lifetime.

• Reduced costs in installation, operation and maintenance.

• Improved safety for a comfortable working environment.

The event, held at conference center of UBS by SCCC at beginning May 2024, brought together the EMBA members from Antai College (ACEM) to explore th

In November 2023, VERTEX was invited as guest speaker to attend the panel discussion regarding tech collaboration, which was organized by Greater Zu

Email:[email protected]

Tel: +41 44 281 9558

Phone number: +86 15221723781

Shanghai, China headquarters address: 1688 East Gaoke Road, Pudong New Area, Shanghai

Copyright © VERTEX. All rights reserved.