When it comes to processing aggregates such as sand, gravel, minerals, or recycled materials, having the right rock crusher is of utmost importance. Whether you're looking to purchase or rent rock crushing equipment, understanding the different types of rock crushers, their applications, and how to select the best option for your project is crucial. This guide will walk you through all the essential information regarding rock crushers for sale and rental options, ensuring you make an informed decision.

Rock crushers are indispensable in industries like mining, construction, and recycling. They break down large rocks into smaller, manageable sizes, producing materials for various applications, including road construction, concrete production, and landscaping. Whether you need a rock crusher machine for a short - term project or a long - term investment, grasping the stages of rock crushing and the available types of rock crushing equipment is the key.

Rock crushing typically involves multiple stages, each necessitating specific types of rock crushing equipment:

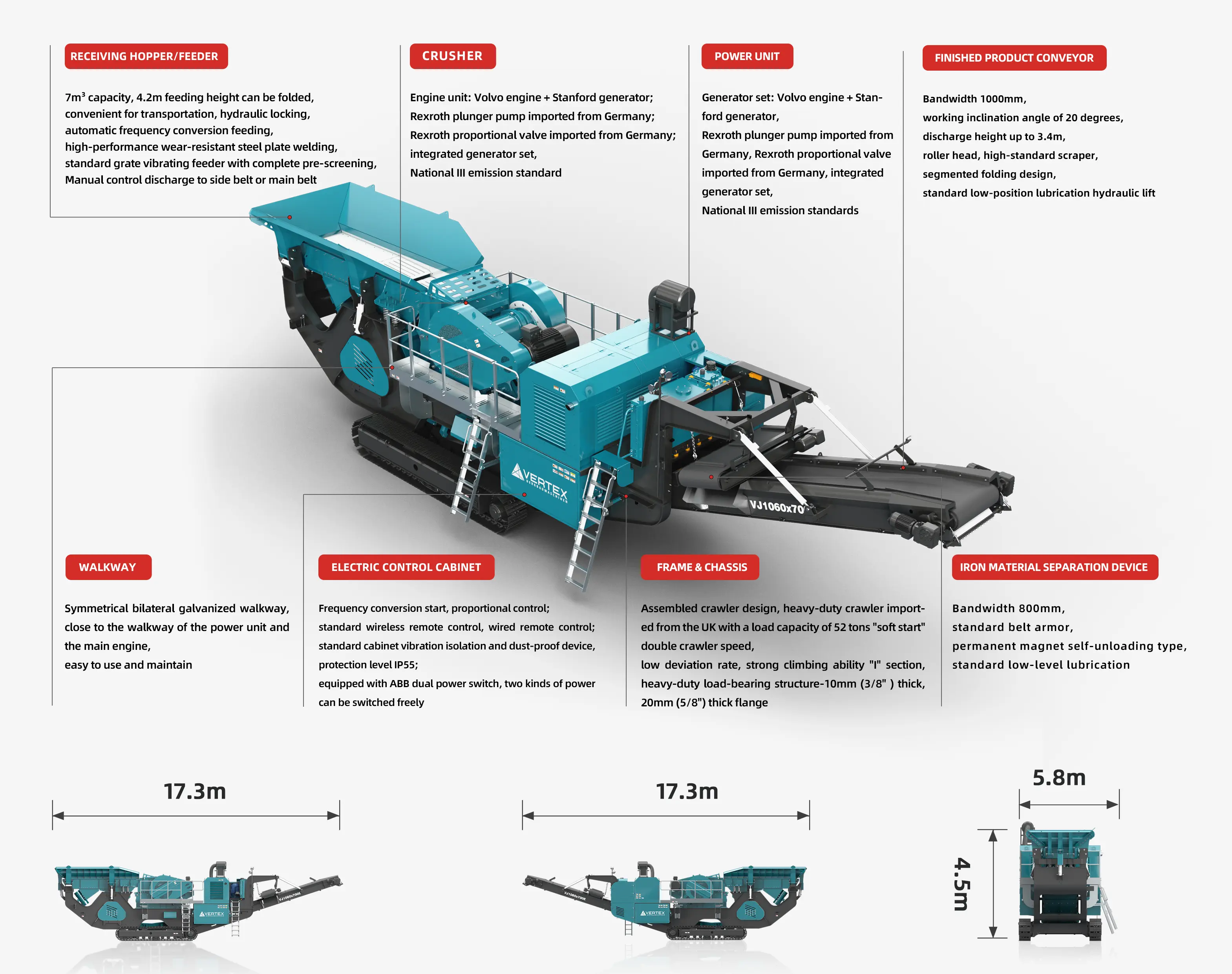

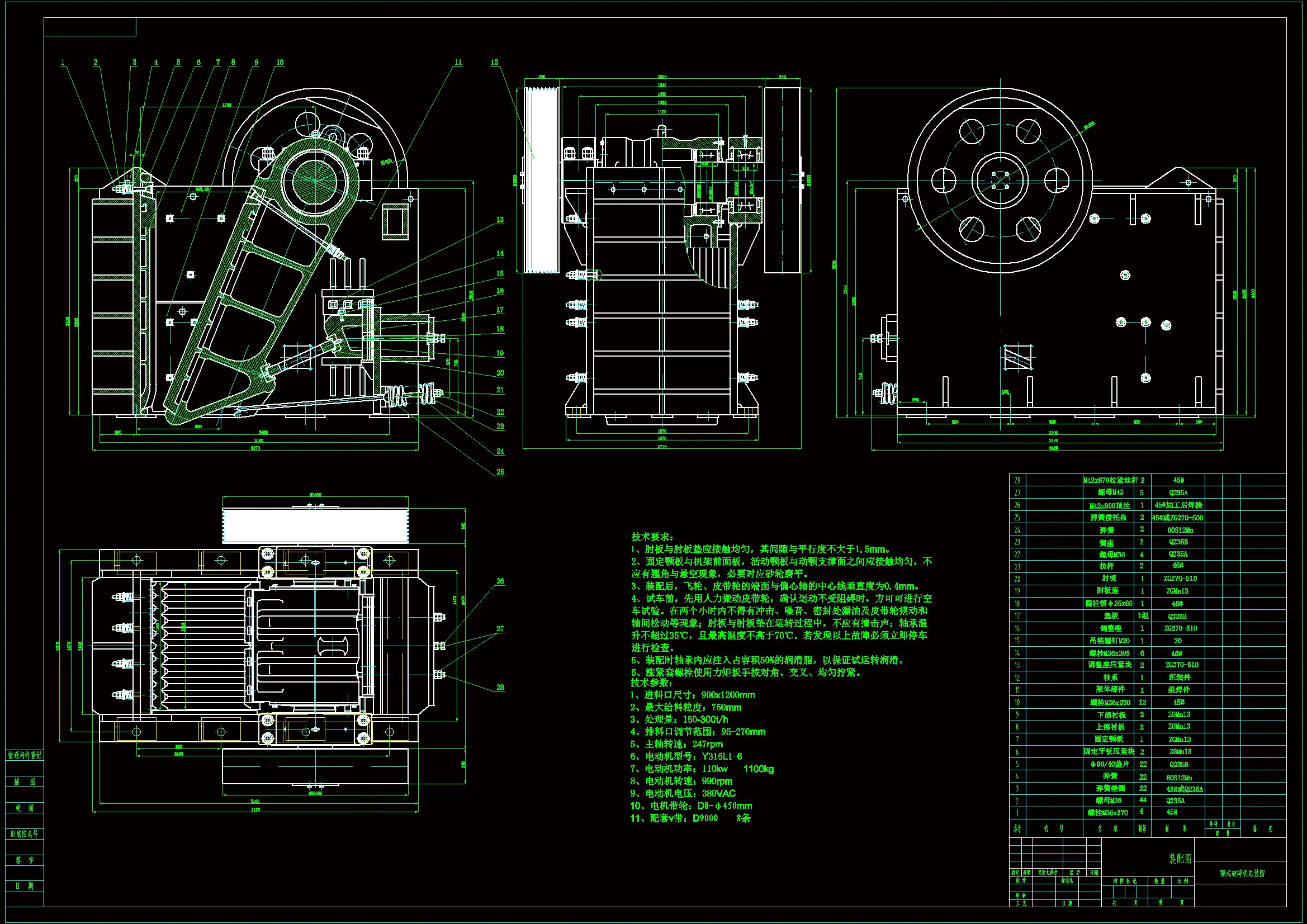

The first stage reduces large rocks to a size suitable for secondary crushing. Common rock crushers for sale in this category include mobile jaw crushers, mobile gyratory crushers, and mobile impact crushers. For example, a mobile jaw crusher is ideal for primary crushing due to its ability to handle large feed sizes and yield consistent output. Its mobility enables it to be easily relocated to different sites, making it a great choice for projects with changing crushing locations. These mobile jaw crushers are among the most popular rock crushing equipment for sale in the market for primary crushing needs.

This stage further reduces the material size. Mobile cone crushers, which are widely available among rock crushers for sale, are often employed here because of their versatility in adjusting settings such as closed - side settings and speed. A mobile cone crusher is a popular choice for secondary crushing, especially in projects that require mobility. It can be transported to different job sites as needed, providing flexibility in operations. When considering rock crushing equipment for secondary crushing, mobile cone crushers stand out for their adaptability.

The final stage shapes the material into the desired product size and shape. Mobile vertical shaft impactors (VSI) and mobile high - pressure grinding rolls, both being important types of rock crushing equipment, are commonly used for this purpose. These machines ensure the final product meets market specifications. If you're looking for rock crushers for sale suitable for the final crushing stages, these two types are worth considering.

The type of rock crusher you need depends on the material you're processing and your project requirements. Here is a breakdown of the most common types:

These are the go - to choice for primary crushing in many mobile applications. They are designed to handle large, hard rocks with ease. The robust structure of mobile jaw crushers allows them to break down boulders into more manageable pieces. Their mobility is a huge advantage, especially for projects where the crushing location needs to be changed frequently, like in small - scale mining operations or construction sites with multiple work areas. Rock crusher for sale options in the mobile jaw crusher category come in different sizes and capacities. They can handle a wide variety of materials and have relatively low wear and tear compared to some other crushers. For example, if you're working on a construction project that involves demolishing an old building and recycling the concrete, a mobile jaw crusher, a popular piece of rock crushing equipment, can be easily moved around the site to crush the large concrete blocks.

Ideal for secondary and tertiary crushing in mobile setups. Mobile cone crushers work by compression, squeezing the material until it breaks apart. They are highly adjustable, allowing you to fine - tune the output size according to your needs. These crushers can handle medium - hard to very hard and abrasive feeds, whether they are dry or wet (but not sticky). When leasing a rock crusher for a construction project that requires well - shaped aggregates for high - quality concrete production, a mobile cone crusher can be a perfect fit. It can be transported to different job sites as needed, providing flexibility in operations. Among the various rock crushers for sale, mobile cone crushers are highly regarded for their performance in secondary and tertiary crushing.

Mobile horizontal shaft impactors (HSI) are used for primary and secondary crushing, while mobile vertical shaft impactors (VSI) are ideal for final shaping. Mobile impact crushers are cost - effective and produce a high reduction ratio, but they are best suited for less abrasive materials. Their mobility allows for on - the - go crushing operations in various project scenarios. These impact crushers are popular rock crushing equipment, especially when cost - effectiveness and high - reduction ratios are crucial.

These are used in high - capacity primary crushing applications, often in mobile mining operations. They offer continuous operation and high efficiency but require a relatively stable setup during operation. Although they are mobile, they still need some preparation when being moved to a new site. Their large - scale design and high - capacity operation make them suitable for handling large volumes of rock in mobile high - output projects. When looking for high - capacity rock crushers for sale for mobile mining operations, mobile gyratory crushers are top contenders in the market of rock crushing equipment.

In recent years, new technologies have been emerging continuously in the field of rock crushers. For instance, intelligent control systems are gradually being applied to rock crushing equipment. These systems can monitor the operating status of the equipment in real - time through sensors, including parameters such as temperature, vibration, and energy consumption. Once an anomaly is detected, the system can issue an alarm in a timely manner and make self - adjustments to avoid equipment failures, greatly improving the stability and continuity of production. Some new - type rock crushers for sale also adopt advanced wear - resistant materials, significantly extending the service life of the equipment and reducing maintenance costs. The development of these technologies has a profound impact on the performance and competitiveness of rock crushers for sale in the market.

The market prices of rock crushers for sale fluctuate due to various factors. On one hand, changes in raw material prices directly affect the production costs of rock crushing equipment. For example, an increase in steel prices will raise the manufacturing costs of crushers, thus increasing the selling price. On the other hand, market supply - demand relationships also play a crucial role. During periods of booming construction industry, the demand for rock crushers surges, often leading to an upward price trend; while when market demand is weak, prices may decline to a certain extent. These price fluctuations need to be carefully considered when making a decision on whether to buy or rent rock crushing equipment.

With the increasingly stringent global environmental requirements, rock crushers are also evolving towards a more environmentally friendly direction. Some manufacturers have developed crushers with low dust emissions. By improving the crushing process and adding dust - removal devices, they effectively reduce the impact of dust on the environment and the health of operators. At the same time, energy - saving rock crushers for sale have also become a new favorite in the market. These devices adopt more efficient power systems and optimized mechanical structures, reducing energy consumption while improving production efficiency, which is in line with the concept of sustainable development.

The innovation driven by environmental trends has brought new options to the market of rock crushing equipment.

Vertex Crushers is a company that offers high - performance crushing equipment. Their products can efficiently and economically produce a wide range of products. Whether you need to process sand, gravel, minerals, or other aggregates, Vertex Crushers has the right solution for you. They are capable of providing custom - designed crushing circuits or retrofitting new rock crushers into your existing operations. If you have any questions regarding rock crushers, feel free to contact Vertex Crushers. Their professional team is always ready to assist you in making the best choice for your project, whether you're interested in rock crushers for sale or rental options of rock crushing equipment.

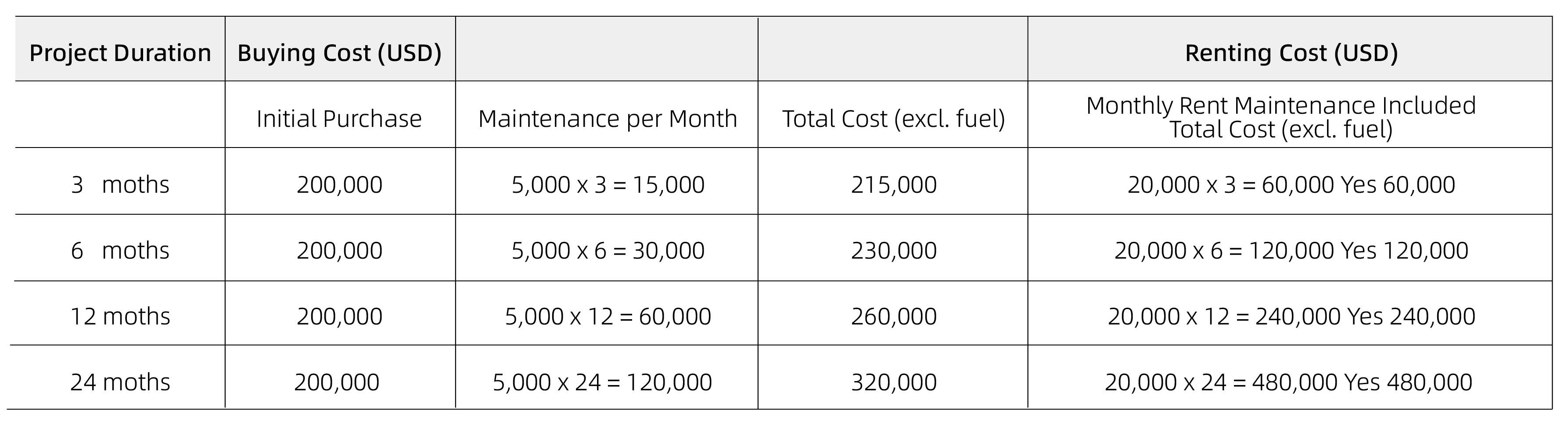

When deciding whether to buy or rent rock crushing equipment, consider the following factors:

For short - term projects, renting a rock crusher machine is often more cost - effective. Rental options such as mobile jaw crushers or mobile cone crushers provide flexibility without the long - term commitment.

Purchasing rock crushers for sale is a significant investment but can be more economical for long - term operations. Evaluate the total cost of ownership, including maintenance and operational costs. To better understand the cost differences between buying and renting, the following table provides a general cost analysis for a mid - sized mobile rock crusher over different project durations:

Please note that these are approximate costs for illustration purposes only. Actual costs may vary depending on the type of crusher, brand, market conditions, and other factors.

If your project involves multiple sites, mobile rock crushers are the best choice. They can be easily transported and set up, reducing downtime and transportation costs.

Owning rock crushing equipment means you're responsible for maintenance. Renting often includes maintenance services, ensuring the equipment operates efficiently throughout your project.

The hardness, abrasiveness, and moisture content of the material will determine the type of rock crusher you need. For example, mobile jaw crushers are ideal for hard, abrasive materials, while mobile impact crushers work best with softer rocks. Different types of rock crushing equipment are designed to handle various material characteristics.

If you need a finely shaped product, consider using a mobile VSI crusher in the final stage. For coarse aggregates, a mobile cone crusher or mobile jaw crusher may suffice. The choice of rock crusher for sale should align with the desired product specifications.

Ensure the rock crusher machine you choose can handle your project's volume. High - capacity machines like mobile gyratory crushers are suitable for large - scale mobile operations, while other mobile crushers are better for smaller projects. Different capacities of rock crushers for sale are available to meet various project demands.

Evaluate fuel consumption, maintenance requirements, and wear - parts replacement costs. For instance, when processing hard materials, mobile cone crushers have lower operating costs compared to mobile impact crushers. These operational cost factors are crucial when choosing rock crushing equipment.

Mobile rock crushers are revolutionizing the industry by offering unparalleled flexibility and efficiency. Here's why they're a great option:

They can be easily moved between job sites without the need for additional equipment.

Minimize downtime with fast installation and commissioning.

They can handle a wide range of materials and applications, from primary to tertiary crushing.

Reduce transportation and operational costs, especially for multi - site projects.

Whether you're planning to buy or rent rock crushers, understanding the different types of rock crushing equipment and their applications is essential. From mobile jaw crushers and mobile cone crushers to mobile impact crushers, each machine has its strengths and is suitable for specific stages of the crushing process. For projects requiring mobility and flexibility, mobile jaw crushers and mobile cone crushers are excellent choices.

By considering factors such as material characteristics, project duration, operational costs, and market dynamics, you can select the right rock crusher machine for your needs. Explore rock crushers for sale or rental options today to ensure your project runs smoothly and efficiently.