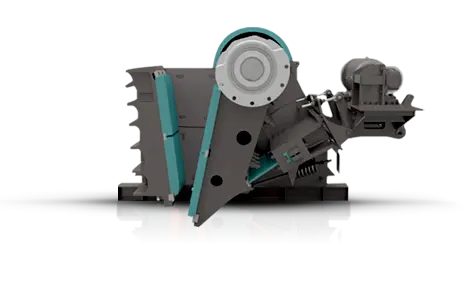

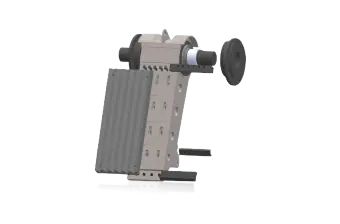

Vertex spare parts factory is a precision casting factory with strong machining capabilities. We provide precision casting and forging parts and machining parts for various crushing equipment, construction machinery, etc., and provide terminal finished parts for global high-end customers with diversified needs, including cutting sheet metal, assembly welding, surface treatment, assembly and other overall solutions and one-stop services.

We have modern workshop, reliable equipment, advanced production technology, committed to producing high quality industrial products for customers, looking forward to sharing and serving with you.

Vertex spare part factory has complete and advanced testing equipment: spectrum analyzer, metallographic microscope, tensile testing machine, low temperature impact testing machine, X-ray flaw detection machine, magnetic particle flaw detection machine, ultrasonic flaw detection machine, coordinate measuring instrument, image measuring instrument, 3D scanner.

The above equipment can ensure the supply of high-standard precision castings to customers, and meet customer's comprehensive testing requirements for physical and chemical properties of materials, non-destructive defect testing, and high-precision geometric size testing.