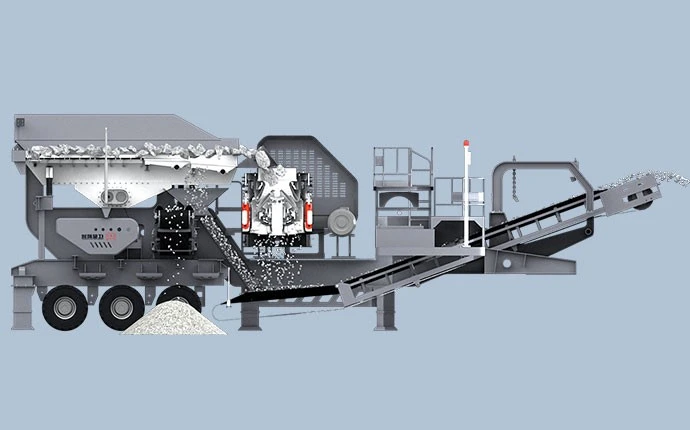

Rock crushers are the core equipment in mining, construction demolition, and aggregate production. This article, combined with real - world scenarios, analyzes how to select Portable Rock Crushers according to project requirements, helping you achieve efficient and low - cost crushing operations.

Rock crushers break down materials such as huge rocks and concrete into aggregates of specific particle sizes through mechanical force, and are widely used in:

Mining: Reducing the size of ore to improve smelting efficiency.

Construction Demolition: Recycling reusable resources such as steel bars and bricks.

Road Construction: Preparing graded crushed stone required for roadbeds.

Industry Trend: A global market research in 2023 shows that the demand for portable rock crushers has increased by 25%. The main reason is that their flexibility and low - carbon characteristics meet the needs of green construction.

Large open - pit granite mines

On - site ChallengesThe size of mined raw stones exceeds 1.2 meters.

The terrain in the mining area is complex, and the transportation cost of traditional equipment accounts for 40% of the budget.

SolutionsUse crawler - mounted mobile jaw crushers for in - situ primary crushing.

Configure a hydraulic adjustment system to quickly set the discharge opening (adjustable from 50 - 300mm).

Key BenefitsThe raw material transportation distance is shortened by 85%.

The service life of high - chromium alloy jaw plates reaches 5,500 hours.

The equipment can climb at an angle of 25° and adapt to mining areas with a 30% slope.

High - quality aggregate production for expressways

On - site ChallengesContinuously supply basalt aggregates with a particle size of 20 - 40mm.

The content of flaky and elongated particles is required to be less than 8%.

SolutionsA hydraulic cone crusher equipped with a laminating crushing chamber.

Equipped with an automatic iron - passing protection device.

Key BenefitsThe proportion of cubic particles is increased to 92%.

The power consumption per ton is reduced to 1.6kW·h through variable - frequency technology.

The equipment transfer preparation time is less than 90 minutes.

Coastal construction solid waste recycling projects

On - site ChallengesProcess concrete ruins containing metal impurities.

The high - salt - fog environment accelerates equipment corrosion.

SolutionsA fully - enclosed structure + 316L stainless - steel impact plates.

Integrated electromagnetic iron remover (separation efficiency of 98%).

Key BenefitsThe chloride ion permeability of the produced recycled aggregates is reduced by 35%.

The service life of the anti - corrosion coating of key components is extended by 4 times.

Supports operation in extreme working conditions from - 20℃ to 50℃.

High - humidity coal crushing operations

On - site ChallengesThe moisture content of raw materials is 15% - 18%.

Material freezing is likely to occur during winter operations.

SolutionsA fully - enclosed crushing chamber + a gas - fired hot air system.

Tungsten carbide composite hammers (wear - resistance index HRC62).

Key BenefitsThe dynamic adjustment range of the grate gap is 30 - 80mm.

Maintains the temperature in the crushing chamber above 3℃, and the blockage rate is less than 3%.

The dust emission concentration is less than 8mg/m³.

Night construction in the city center

On - site ChallengesConstruction hours are limited to 22:00 - 05:00.

The site width is limited to less than 3 meters.

SolutionsUltra - quiet design (operating noise less than 55dB).

A modular screen mesh quick - replacement system.

Key BenefitsThe screening efficiency is 400t/h, and it can support the simultaneous output of 4 specifications.

The equipment width is compressed to 2.8 meters, and it can pass through standard municipal culverts.

The rubber spring shock - absorption system reduces the vibration transmission rate by 60%.

Pretreatment of complex - composition ores

On - site ChallengesThe raw ore contains 25% soil and organic impurities.

Direct crushing shortens the equipment wear cycle by 70%.

SolutionsA combined system of a three - stage trommel screen and a bounce screen.

A self - cleaning brush anti - blocking design.

Key BenefitsEffectively removes impurities less than 5mm, and the pass rate is increased to 97%.

he service life of crusher wearing parts is extended to 650 hours.

The processing capacity of viscous materials is increased by 3 times.

Sand - making operations in areas without water and electricity

On - site ChallengesLack of stable water and electricity supply in desert areas.

Need to produce machine - made sand for C60 concrete.

SolutionsDiesel - powered drive + air self - circulation dust removal.

Dual - mode switching between stone - on - stone/stone - on - iron.

Key BenefitsThe fineness modulus of the produced sand is 2.8 ± 0.2.

The daily output of a single machine exceeds 3,500 tons.

The air consumption of the dust removal system is less than 4m³/min.

For mountainous/mining areas, give priority to crawler - type (ground contact pressure less than 35kPa).

For multi - site rotation operations, choose tire - type (transfer speed greater than 25km/h).

Equipment theoretical production capacity = (raw material hardness coefficient × motor power) / (target particle size index × humidity correction value)

| Cost Type | Mobile Jaw Crusher | Mobile Cone Crusher | Mobile Impact Crusher |

|---|---|---|---|

| Cost per ton of purchase (yuan) | 80 - 120 | 150 - 200 | 100 - 150 |

| Cost per ton of maintenance (yuan) | 0.7 | 1.1 | 0.9 |

Real - time monitoring of bearing temperature and vibration spectrum, warning of faults 48 hours in advance (reducing unexpected downtime losses by 30%).

Diesel - electric dual - mode drive (saving 25% energy in field conditions and switching to pure - electric mode in urban conditions).

Nanocomposite tungsten carbide coating technology enables the service life of blow bars to exceed 8,000 hours.

Granite/Basalt → Jaw Crusher + Cone Crusher

Limestone/Coal → Impact Crusher/Hammer Crusher

For materials with a moisture content of more than 10%, give priority to cone crushers (impact crushers are prone to blocking).

Narrow spaces: Crawler - type equipment (turning radius less than 6m).

Multi - site operations: Tire - type equipment (transfer speed greater than 30km/h).

| Equipment Type | Purchase Cost (10,000 yuan) | Cost per Ton of Maintenance (yuan) |

|---|---|---|

| Mobile Jaw Crusher | 120 - 200 | 0.8 |

| Mobile Cone Crusher | 250 - 400 | 1.2 |

| Crawler Impact Crusher | 180 - 300 | 1.5 |

Noise limit: Less than 65dB in urban areas (choose equipment equipped with sound - proof enclosures).

Dust emission: PM2.5 concentration less than 50μg/m³ (install a dry fog dust suppression system).

Vertex Bergbaumaschinen's equipment is equipped with an AI prediction system, which can predict bearing failures 7 days in advance through vibration sensors, reducing downtime losses by 200,000 yuan per time.

Our Territory Group's electric crawler chassis reduces carbon emissions by 45% compared with diesel models, which is suitable for areas with strict environmental control.

The golden combination of jaw crusher (primary) → cone crusher (secondary) → VSI (sand - making) can improve comprehensive benefits.

Give priority to examining local service outlets (response time less than 4 hours) and spare parts inventory (meeting 80% of the needs of vulnerable parts).

Through accurate selection and scientific operation and maintenance, portable rock crushers can help you increase production efficiency by more than 30% and reduce the cost per ton by 15 - 20 yuan. Take action now and make rock crushing a profit growth point for you!