When it comes to crushing rocks, concrete, and recycled materials, impact crushers are the unsung heroes of modern construction and mining. But what exactly are impact crushers, and why are they indispensable in concrete production? At Vertex Bergbaumaschinen, we combine cutting-edge engineering with decades of expertise to deliver impact crushers that redefine efficiency, durability, and versatility. Let's explore how our solutions, like the VI Impact Crusher and VCI Crawler Mobile Impact Crusher, empower industries worldwide.

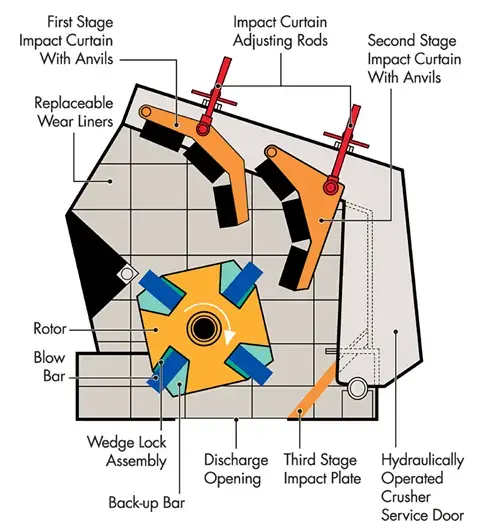

At their core, impact crushers are like industrial-sized pinball machines for rocks. A high-speed rotor—armed with hammers or blow bars—spins at incredible velocities, hurling materials against a solid impact wall. The collision shatters the material into smaller pieces, which ricochet between the rotor, walls, and other particles until they’re small enough to escape through the bottom. The result? Uniform, cubical-shaped aggregates that are perfect for concrete mixes, road bases, and more.

Vertex Bergbaumaschinen’s Secret Sauce: OurVI Impact Crusherseries uses a precision-engineered rotor system and multi-stage impact walls to maximize crushing efficiency while minimizing wear.

Model VI110: Designed for high-volume concrete sand production.

Rotor Spec: φ1100x1000 mm

Capacity: 110–260 t/h

Power: 160–200 kW

Perfect For: Producing uniform, cube-shaped aggregates for premium concrete mixes.

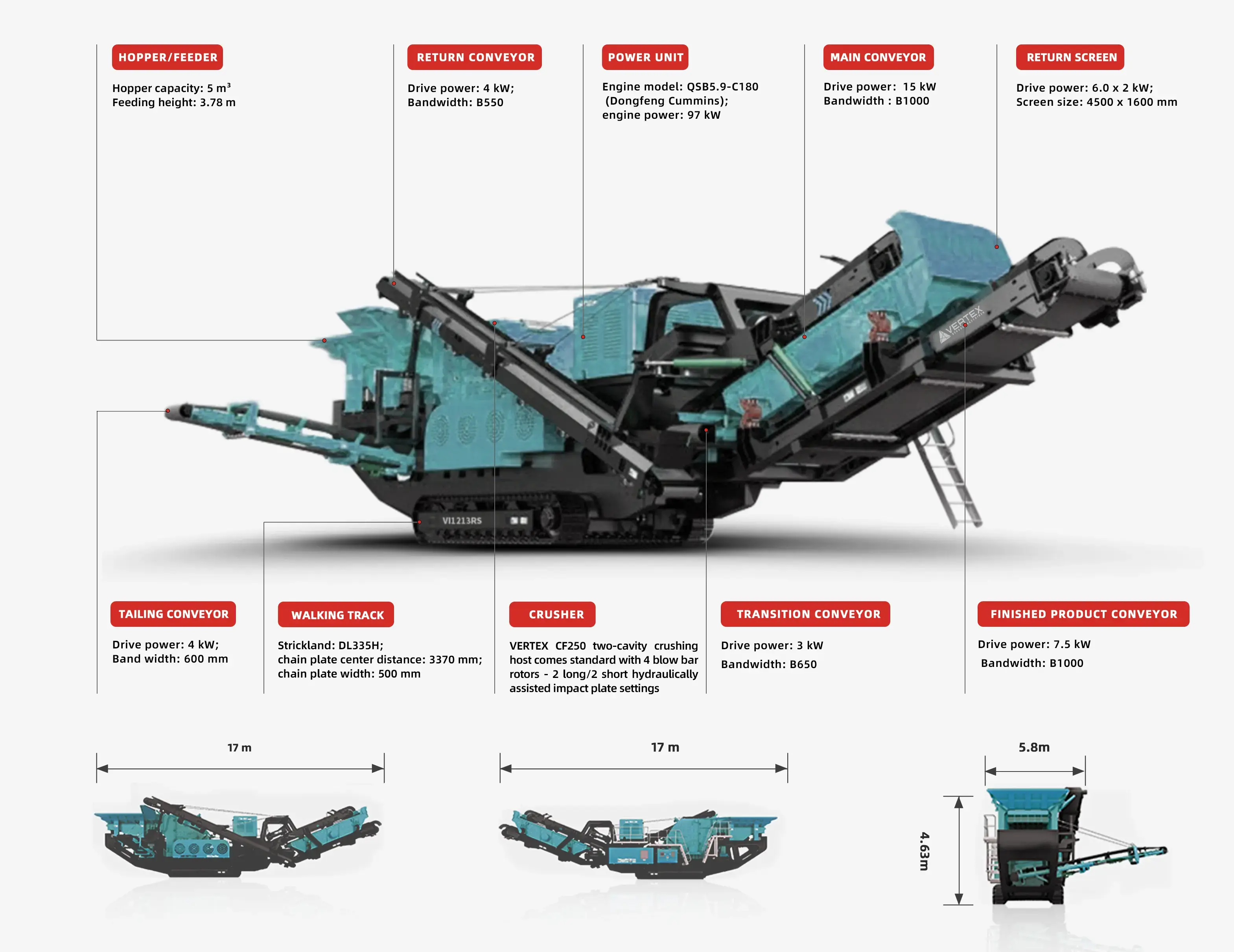

Mobility Meets Power: Walk into any job site and start crushing.

Feeding Capacity: Up to 500 t/h

Processing Capacity: 200–400 t/h

Crusher Power: 280 kW

Ideal For: On-site recycling of concrete debris or remote quarry operations.

Concrete demands precise, durable aggregates. Here’s how our crushers deliver:

Cubical Perfection: The VI110’s vertical shaft design ensures 95%+ cubical output, reducing voids in concrete.

Smart Adjustability: Hydraulic apron controls let operators tweak output size on the fly—no downtime.

Go Anywhere: With a crawler chassis and 55 kW walking engine, tackle rugged terrains effortlessly.

High Capacity: Crush up to 700 mm feed material into reusable aggregates at 400 t/h.

Vertex Bergbaumaschinen’s crushers are engineered for endurance:

Rotor & Blow Bars: Forged from ultra-wear-resistant alloys, our VI110 rotor withstands concrete’s abrasive nature.

Impact Walls with Replaceable Liners: Quick-swap wear plates keep operations running smoothly.

Smart Hydraulic Systems: Adjust aprons remotely to maintain consistent output, even as components wear.

We’re pioneering the next generation of impact crushers:

IoT Integration: Real-time monitoring of rotor speed, wear levels, and output quality via Vertex’s proprietary dashboard.

Eco-Mode Operations: Reduce energy consumption by 15% without sacrificing productivity.

AI-Powered Optimization: Automatically adjust settings based on material hardness for peak efficiency.

Q: Can the VCI Mobile Crusher handle large concrete slabs?

A: Absolutely! With a 700 mm max feed size, it devours demolition waste like a hungry giant.

Q: How long do VI110 blow bars last in concrete recycling?

A: With Vertex’s hardened steel bars, expect 800–1,200 hours of service—twice the industry average.

Q: What support does Vertex offer?

A: From installation to wear part replacements, our global service network ensures minimal downtime.

Proven in the Field: Our VI and VCI crushers are trusted in 30+ countries for infrastructure and mining projects.

Sustainability Focus: Turn 100% of concrete waste into high-value aggregates—cut costs and carbon footprints.

Custom Solutions: Need a crusher tailored to your site? We engineer to your specs.

Picture this: A demolition site in Berlin. Using the VCI Crawler Mobile Impact Crusher, crews transform 500 t/h of rubble into pristine aggregates for a new high-rise's foundation. Meanwhile, a quarry in Brazil relies on the VI110 to produce flawlessly shaped sand for critical concrete projects.

Whether you're recycling urban waste or processing virgin rock, Vertex Bergbaumaschinen's impact crushers are your ultimate partners. Explore our VI Impact Crusher series for stationary precision or embrace mobility with the VCI Crawler Mobile Impact Crusher.

Contact Vertex Bergbaumaschinen today—let's build the future, one perfect aggregate at a time.