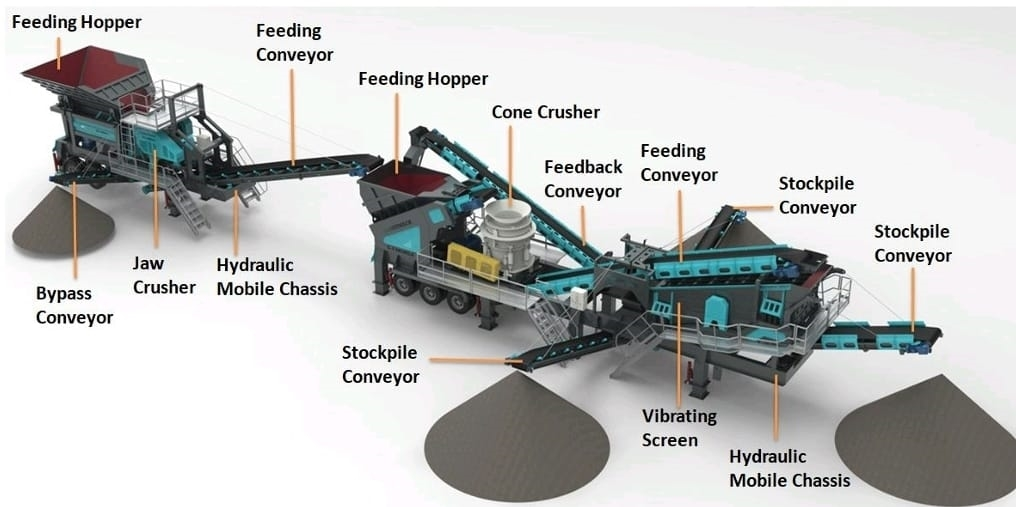

A rock crusher is a heavy-duty machine designed to break down large rocks, ores, and construction debris into smaller, manageable pieces. Portable rock crushers, on the other hand, offer mobility and flexibility, allowing operators to crush materials directly at job sites. Both types of equipment use mechanisms like compression, impact, or attrition to reduce material size. These machines are indispensable across industries such as mining, construction, and energy, serving as the backbone of material processing operations.

In mining, rock crushers are critical for primary crushing. They process hard rocks like granite, iron ore, and copper ore into smaller fragments for further refining. Portable rock crushers shine in remote mining locations where transporting raw materials to fixed plants is costly. For example, a gold mine in Australia reduced transportation expenses by 40% by deploying a portable rock crusher on-site, enabling real-time ore processing and faster project turnaround.

Metallurgy relies on rock crusher machines to prepare ores for smelting. High-hardness materials like copper and gold ores require robust crushing solutions to achieve uniform particle sizes. Advanced rock crusher machines incorporate energy-efficient designs, reducing power consumption by up to 25% compared to traditional models. This innovation helps metallurgical plants meet sustainability goals while maintaining productivity.

Portable rock crushers play a vital role in chemical and energy sectors. They crush limestone and gypsum for chemical production and process coal for power generation. In biomass energy plants, portable units crush organic materials into fuel pellets. Their compact design and low emissions make them ideal for environmentally sensitive areas like chemical parks.

Construction waste, such as concrete, bricks, and asphalt, is transformed into reusable aggregates using rock crushers. A portable rock crusher deployed at a demolition site in Berlin processed 500 tons of debris daily, achieving “zero waste” by converting 95% of materials into recycled gravel for new projects. This approach slashes landfill costs and supports circular economy initiatives.

Aggregates are the foundation of construction projects. Rock crusher machines ensure consistent output, producing gravel and sand that meet strict building standards. In a large quarry in Texas, fixed and portable rock crushers work in tandem: fixed units handle bulk crushing, while mobile units adjust to shifting production demands, boosting efficiency by 30%.

Portable rock crushers excel in road construction, especially in remote areas. They crush on-site rock into base materials for pavements, eliminating the need to import aggregates. During a highway project in the Canadian Rockies, a portable rock crusher reduced material costs by 20% and accelerated timelines by processing rocks directly at the construction site.

Fixed rock crushers: Ideal for high-volume, long-term operations like mines or large quarries.

Portable rock crushers: Perfect for short-term projects, offering rapid setup and relocation.

ROI comparison: While fixed crushers have lower operating costs, portable models reduce logistics expenses by 15-30%, making them cost-effective for mobile projects.

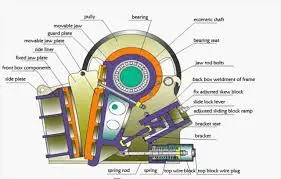

To maximize the lifespan of your rock crusher machine:

1.Lubricate bearings and jaws weekly to prevent wear.

2.Replace manganese liners every 500-1,000 hours in high-abrasion environments.

3.Optimize energy use by adjusting feed rates and crusher settings. For portable rock crushers, inspect tires and hydraulics before relocation to avoid downtime.

From mining to urban recycling, rock crushers and portable rock crushers are transformative tools across industries. Their ability to process diverse materials efficiently addresses critical challenges like cost reduction, sustainability, and operational flexibility. As technology advances—think AI-driven automation and hybrid power systems—these machines will continue to redefine productivity. Whether you're crushing ores in a mine or recycling concrete in a city, choosing the right crusher ensures long-term success.