Maintaining and optimizing crushing equipment is a critical task for businesses in mining, construction, and recycling. One of the most important decisions you'll face is whether to choose OEM (Original Equipment Manufacturer) parts or aftermarket parts. This choice can significantly impact your equipment's performance, operational costs, and longevity. In this blog, we'll explore the key benefits of OEM parts, explain what OEM means, and why they are often the superior choice for your crushing needs.

Before diving into the benefits, let's clarify what OEM means. OEM stands for Original Equipment Manufacturer. These are companies that produce parts and equipment specifically designed for their own machinery. In the context of crushers, OEM parts are manufactured by the same company that built the original equipment, ensuring perfect compatibility and performance.

OEMs are manufacturers who create products or components that are used in another company’s end product. For example, in the crusher industry, an OEM produces both the crushing equipment and the spare parts that go with it. This ensures that every component meets the same high standards as the original machine.

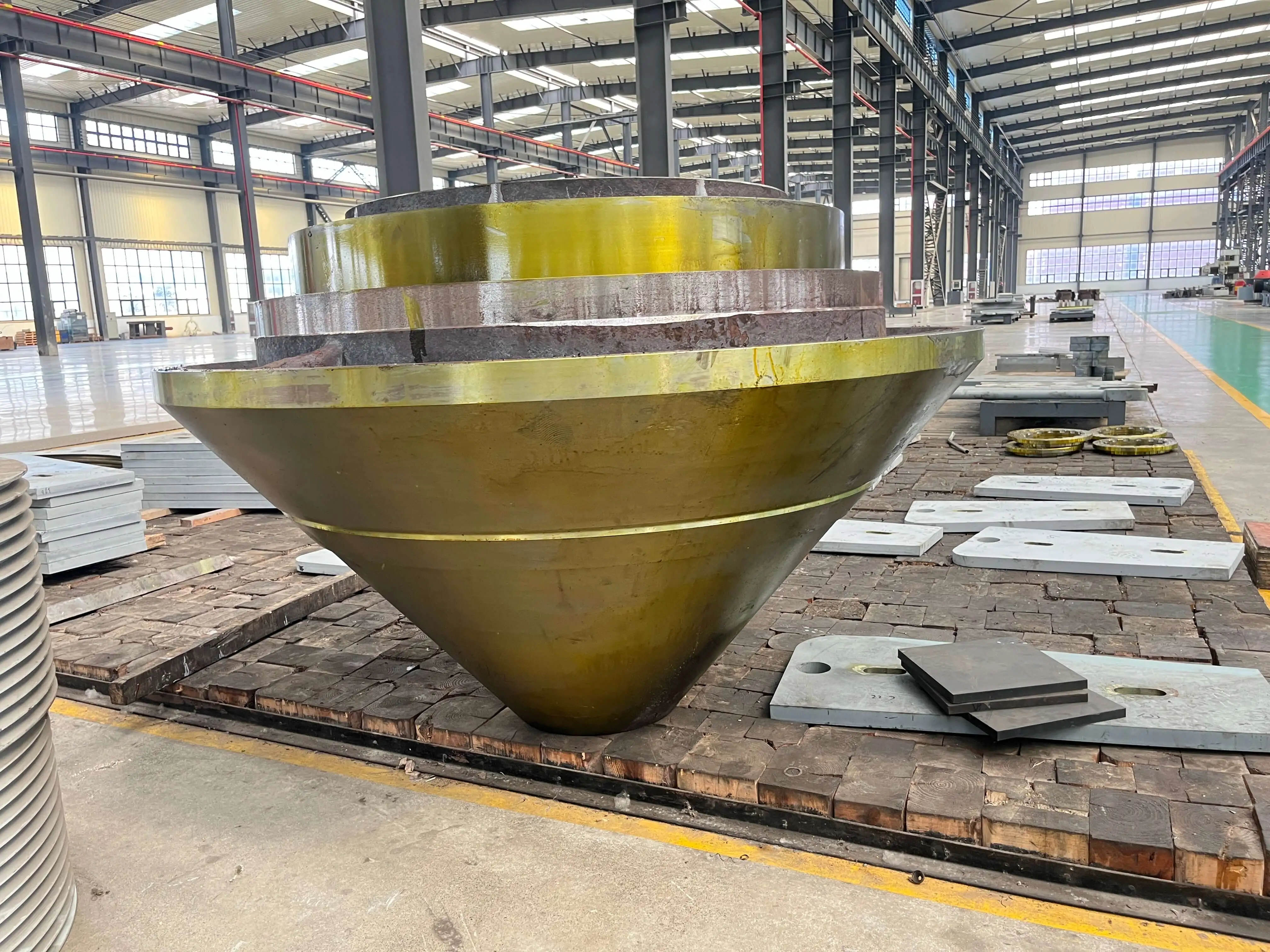

As a leading manufacturer in the crusher industry, we specialize in producing high-quality crushing equipment and precision-engineered spare parts. Our role as an OEM ensures that every part we produce meets the same rigorous standards as the original equipment, guaranteeing compatibility and reliability. Our expertise and commitment to quality have made us a trusted name in the industry.

In industries like mining and construction, equipment downtime can lead to significant financial losses. OEM parts are designed specifically for your equipment, ensuring optimal performance even under the most demanding conditions. By using OEM parts, you can minimize the risk of unexpected breakdowns and keep your operations running smoothly.

For example, in mining operations, crusher downtime can cost thousands of dollars per hour. OEM parts are engineered to withstand harsh conditions, ensuring your equipment operates efficiently and reliably. Unlike aftermarket parts, which may fail prematurely, OEM parts are built to last, reducing the risk of costly interruptions.

We invest heavily in research and development to create parts that outperform industry standards. OEM parts are made from high-strength materials and manufactured using advanced techniques, ensuring superior durability and performance. Whether you're processing hard rock or abrasive materials, OEM parts are designed to deliver exceptional results.

For instance, our parts are crafted using cutting-edge technology and premium materials, making them more resistant to wear and tear than aftermarket alternatives. This focus on innovation ensures that OEM parts not only meet but exceed the demands of modern crushing operations.

Choosing OEM parts means more than just high-quality components—it means access to unparalleled customer support. From technical consultations to installation guidance, our team of experts is always ready to assist you. Additionally, all OEM parts come with a manufacturer's warranty, providing peace of mind and added value.

While OEM parts may have a higher upfront cost compared to aftermarket parts, their long-term benefits far outweigh the initial investment. OEM parts reduce the frequency of replacements, lower maintenance costs, and improve overall equipment efficiency. When you consider the total cost of ownership (TCO), OEM parts are the more economical choice.

For example, although OEM parts may cost more initially, their durability and reliability can reduce maintenance costs by up to 30%. By minimizing downtime and extending equipment life, OEM parts deliver significant savings over time.

The crusher industry is evolving, with a growing emphasis on automation and smart technology. As these trends gain momentum, the demand for high-quality OEM parts will continue to rise. We are committed to staying at the forefront of this transformation, developing innovative solutions to meet the changing needs of our customers.

Every business must balance budget constraints with the need for efficiency. When purchasing parts for your crusher, it's essential to consider both cost and performance. OEM parts offer the perfect balance—delivering long-term value without compromising on quality.

OEM Parts: Manufactured by the original equipment manufacturer, these parts are identical to the ones used in your crusher, ensuring perfect compatibility and performance.

Aftermarket Parts: Produced by third-party manufacturers, these parts may offer similar functionality but often lack the quality and precision of OEM parts.

Quality and Compatibility: OEM parts are designed and tested to meet strict manufacturer standards, ensuring a perfect fit and optimal performance.

Durability: Made from high-quality materials, OEM parts last longer and help extend the life of your equipment.

Cost Savings: While the initial cost may be higher, OEM parts reduce the need for frequent replacements and repairs, saving you money in the long run.

Warranty and Support: OEM parts come with manufacturer warranties and access to expert support, providing added peace of mind.

Aftermarket parts may seem appealing due to their lower cost, but they often come with hidden risks. Poor quality, inconsistent performance, and lack of warranty support can lead to higher long-term costs and operational inefficiencies.

By choosing OEM parts, you can minimize mechanical issues, extend equipment life, and maintain operational efficiency. This is especially critical for large-scale projects where equipment failure can result in significant delays and expenses.