The jaw crusher, a cornerstone of modern material processing, traces its roots back to 1858 when American inventor Eli Whitney Blake designed the first mechanical rock-crushing machine. Over 160 years of innovation, jaw crushers have evolved into highly efficient machines integral to mining, construction, and recycling. Today, advancements in IoT and AI are reshaping the industry. Vertex Bergbaumaschinen exemplifies this shift with its intelligent control systems, enabling real-time performance optimization and predictive maintenance. Future trends lean toward automation, energy efficiency, and eco-friendly designs—priorities that align with global sustainability goals.

Material Innovation: High manganese steel (Mn18Cr2) remains the standard for durability, but Vertex Bergbaumaschinen takes it further with nano-tungsten-carbide coatings, tripling wear resistance in high-abrasion environments like iron ore crushing.

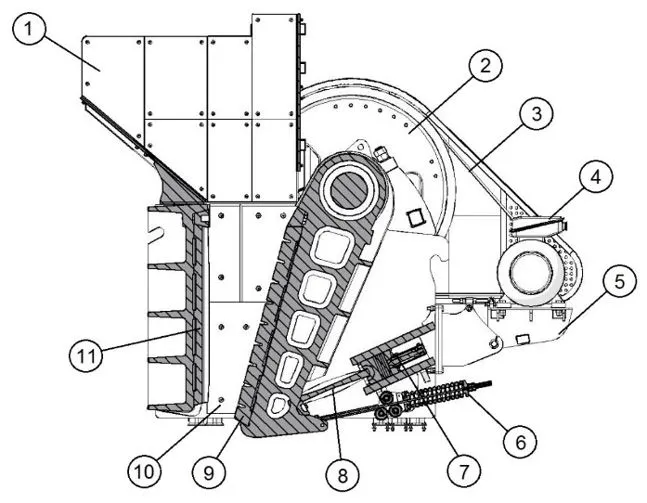

Function: These plates act as the "teeth" of the crusher, directly engaging with raw materials.

Role: Drives the movable jaw in a cyclical motion to crush materials.

Vertex Advantage: Forged from high-strength alloy steel, our shafts minimize fracture risks even under extreme loads.

Hydraulic vs. Mechanical: Hydraulic systems (used in Vertex crushers) enable precise discharge gap adjustments (±2mm accuracy) in under 5 minutes, compared to hours for manual systems.

Automation: Centralized lubrication reduces manual intervention, extending bearing life by 30%.

Client Background: A leading Indonesian mining company specializing in iron ore and copper extraction faced challenges with frequent downtime and high maintenance costs due to abrasive ores.

1. Deployed a Vertex C-Series Jaw Crusher with nano-coated jaw plates.

2. Optimized feed rate and discharge settings for 50–100mm output, ideal for downstream ball milling.

1. 25% increase in crushing efficiency.

2.Annual cost savings exceeding $200,000.

Client Background: A South African construction firm managing large-scale demolition projects needed to recycle concrete debris into reusable aggregates.

Implemented a Vertex Portable Jaw Crusher with a built-in steel-bar separator.

Crushed concrete waste to 20-50mm recycled aggregates, meeting ASTM C33 standards.

95% waste conversion rate.

Annual landfill cost reduction: $150,000.

.webp)

Coal Crushing: Vertex crushers process coal to 30-50mm for power plants, reducing fuel preparation costs by 18%.

Limestone Processing: Crushed limestone (10-30mm) is used in cement production, enhancing kiln efficiency.

Uniform Feeding: Use vibrating feeders to prevent overload and uneven wear.

Real-Time Monitoring: Vertex's IoT-enabled sensors track temperature, vibration, and throughput, alerting operators to anomalies.

Daily Checks: Inspect jaw plates, lubricant levels, and belt tension.

Jaw plates: Every 1,000-1,500 hours.

Bearings: Every 3,000-5,000 hours.

Vertex Support: 24/7 remote diagnostics and 48-hour emergency spare parts delivery.

Vertex's Intelligent Frequency Drive (IFD): Reduces power consumption by 15–20%, equivalent to $50,000 annual savings for a mid-sized quarry.

Regenerative Braking: Captures kinetic energy during operation, feeding it back into the grid.

Dust Suppression: Integrated water sprays and enclosed crushing chambers reduce particulate emissions by 90%.

Noise Reduction: Soundproofing materials lower operational noise to 75 dB, complying with urban regulations.

Proven Durability: 5-year warranty on core components, backed by a 30% lower failure rate than industry averages.

Adaptability: Modular designs cater to mines, quarries, and urban job sites.

Global Support: Multilingual technical teams and localized service hubs ensure uninterrupted operations.

Jaw crushers are more than machines—they are strategic assets driving productivity and sustainability. From Indonesia's mines to South Africa's construction sites, Vertex Bergbaumaschinen delivers cutting-edge solutions tailored to your needs.

Contact Vertex Bergbaumaschinen Today for a free efficiency audit and discover how our jaw crushers can slash your operational costs while boosting output.